Designing and building a sound sculpture with 3D printed parts

In the Digital Humanities Lab, students and staff can make use of various technical facilities. PhD student Caeso tells us more about his experiences with the printer in the Maker Space.

During a large part of 2025 I had the chance to use the facilities of the Digital Humanities Lab (Huizinga), in particular its 3D printer, to develop one of my research projects. As a PhD candidate in artistic research in music at ACPA, the Academy of Creative and Performing Arts of Leiden University, my research has a strong practical component in art making. In my case, composing in a very expanded sense. The project at hand, for example, is a sound sculpture that had the most important part of its physical structure 3D printed.

Designing and building a sound sculpture with 3D printed parts

The sonic principle is simple: feedback. But for that to happen with piezos – a specific kind of transducer –, it is necessary for them to physically touch each other. So, the most important and time-consuming part of the project was to design a structure to hold the piezos in place. Not too tight, because the piezos need to vibrate, allowing also some room for playfulness and variation. Not so perfect that it loses its craft quality, while still having enough symmetry for feedback to happen and for a general look to take shape. And in such a way that the whole sculpture can be disassembled for transportation and storage so that my future self does not hate my past one: when you do not own a car, are not allowed to drive one (at least not in this part of the planet), and live in a bedroom, these things become a survivalist skill.

Having previously coordinated a school makerspace, I had the chance to develop quite some understanding of the potentials and limitations of such digital fabrication methods, and playing along with both – limitations included – has long been a part of my creative process. This sort of DIY, see-through aesthetics that hide no mystery as to how a piece actually works is precisely what I aim for: simplicity in a (relatively speaking, especially since the 3D printer was available for my usage) cheap package. There is no trick, no secret. But coming to terms with the general size and appearance of the artwork was a long process, and even longer were the adjustments of its proportions. Despite the fact that 3D printers are capable of producing quite precise pieces, they also have a margin of tolerance that can oscillate according to a number of factors: the shape being printed, its general scale, the kind of filament and temperature settings, and a range of other parameters. This gets particularly complicated when you are dealing with articulated connections, as I was. And as the project changed along the way, most of these adjustments had to be reset and test-proofed once more, as they are not always predictable. A lot of trial and error was necessary to achieve the necessary qualities of the sculpture's final outcome.

Yet, here we are. After so much prototyping, I believe I have reached a final version, even if final only for the time being. Having easy access to the 3D printer definitely helped make this project see the light of day (big thanks to Janessa Leeuwis for the help setting everything up!), but that does not mean that the work is over. Since so much has changed from the initial project, its poetic features metamorphosed into something else, and now I have to rediscover it, the creator getting to know the creature. The artwork, for example, currently has no name: I tried asking, but I could not really understand what it screeched back as an answer...

Sound Sculpture

Due to the selected cookie settings, we cannot show this video here.

Watch the video on the original website or(video: Thomas Vorisek / audio: Caeso)

Caeso.

PhD candidate Academy of Creative and Performing Arts, Leiden University

caeso.mus@gmail.com

https://www.caeso.info/

-

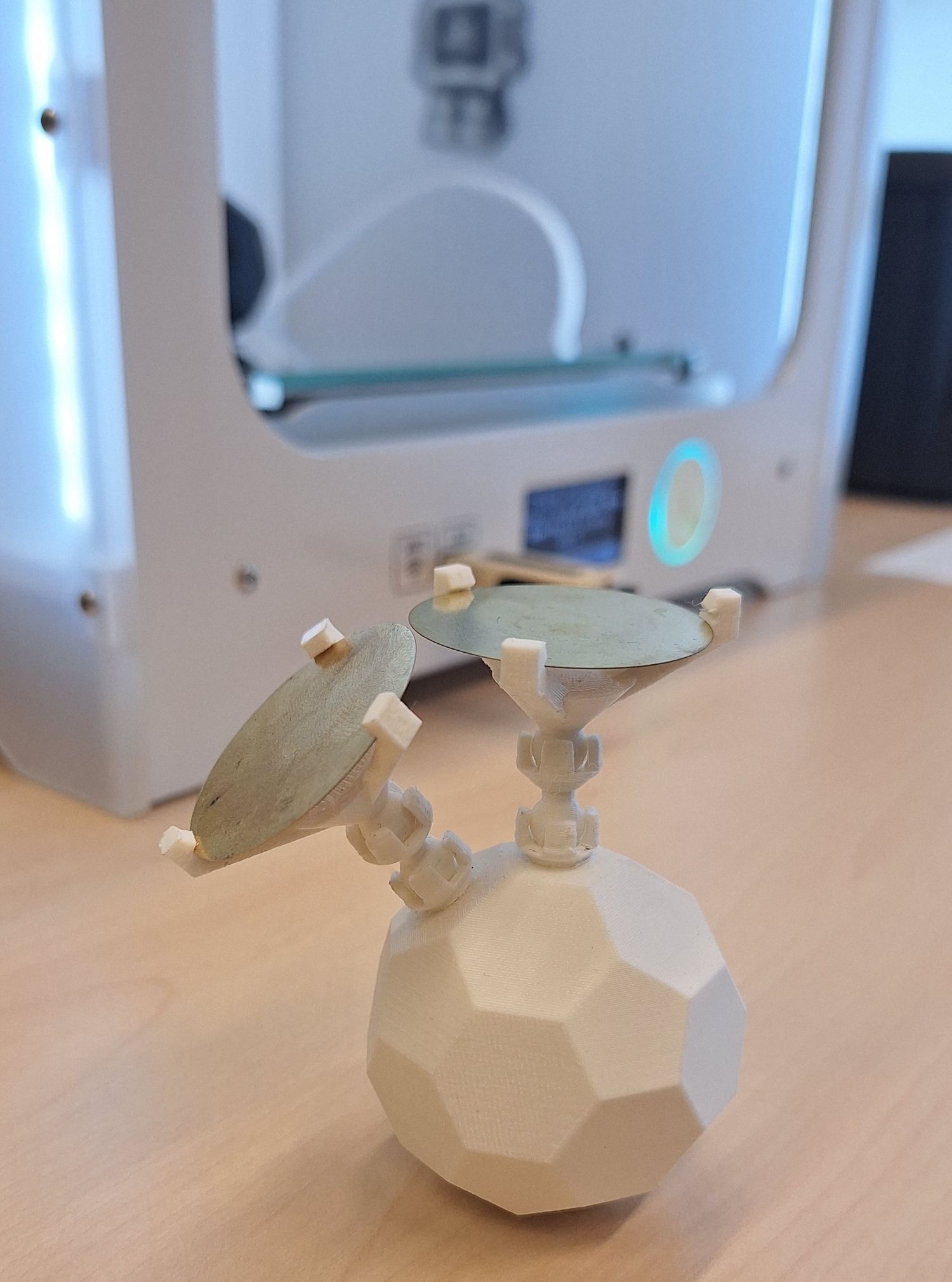

Early prototype for the 3D printed structure (photo: Caeso) -

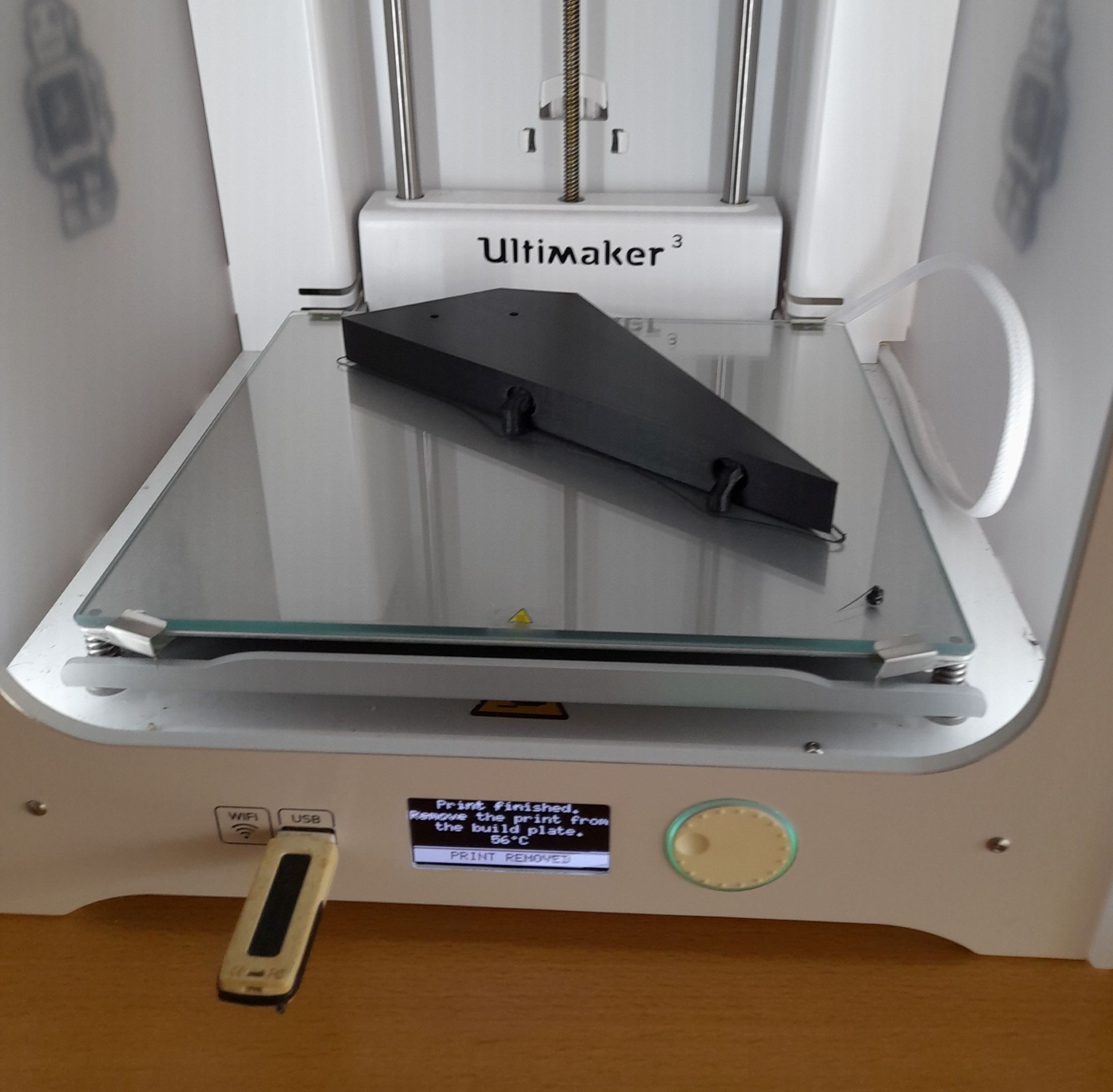

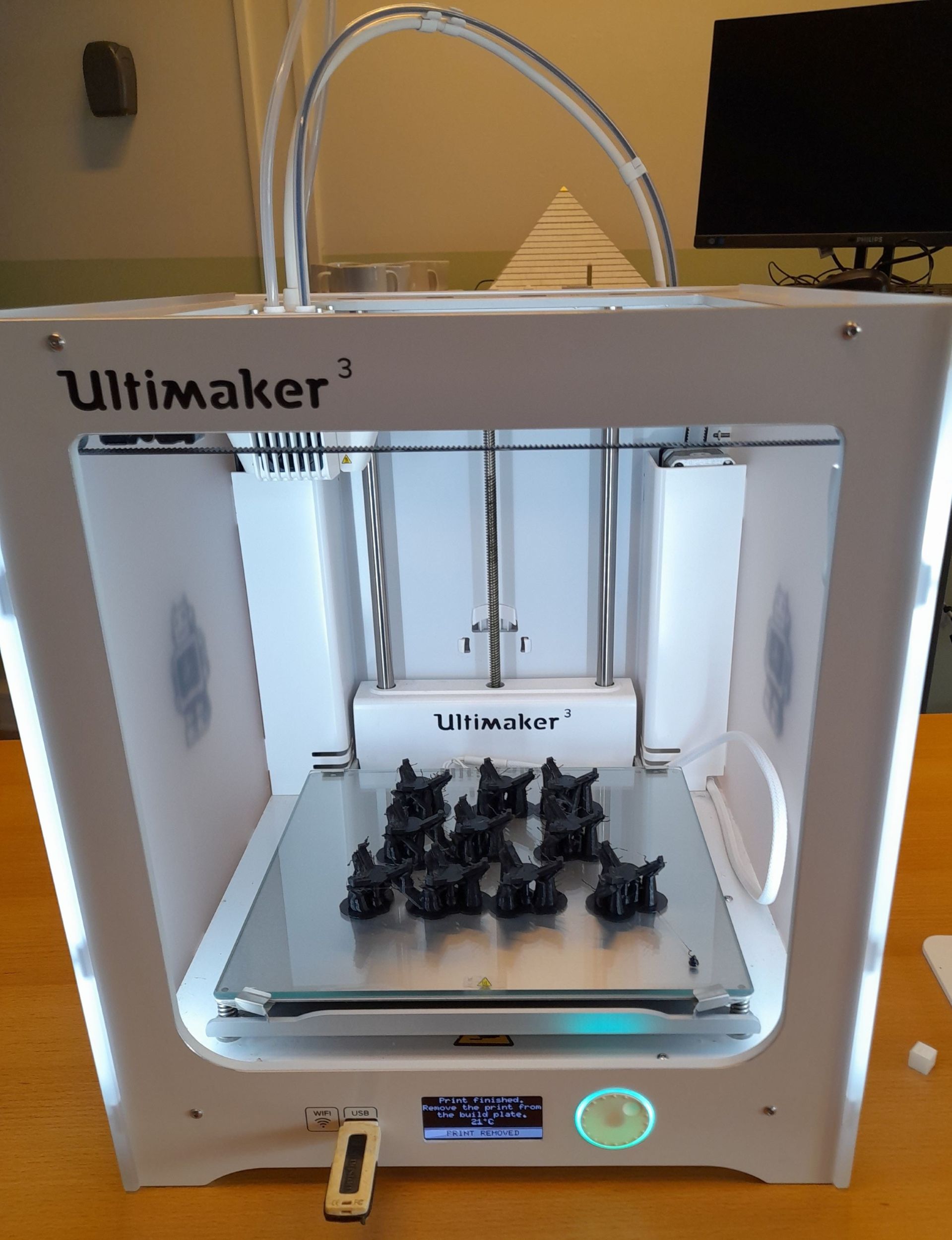

3D printing of parts on Ultimaker (photo: Alison) -

3D printing of parts on Ultimaker (photo: Alison) -

Some of the parts for the sculpture assembly (photo: Caeso) -

Close-up of the piezo made spheres (photo: Caeso) -

Close up of the sculpture (photo: Keven Fairbairn) -

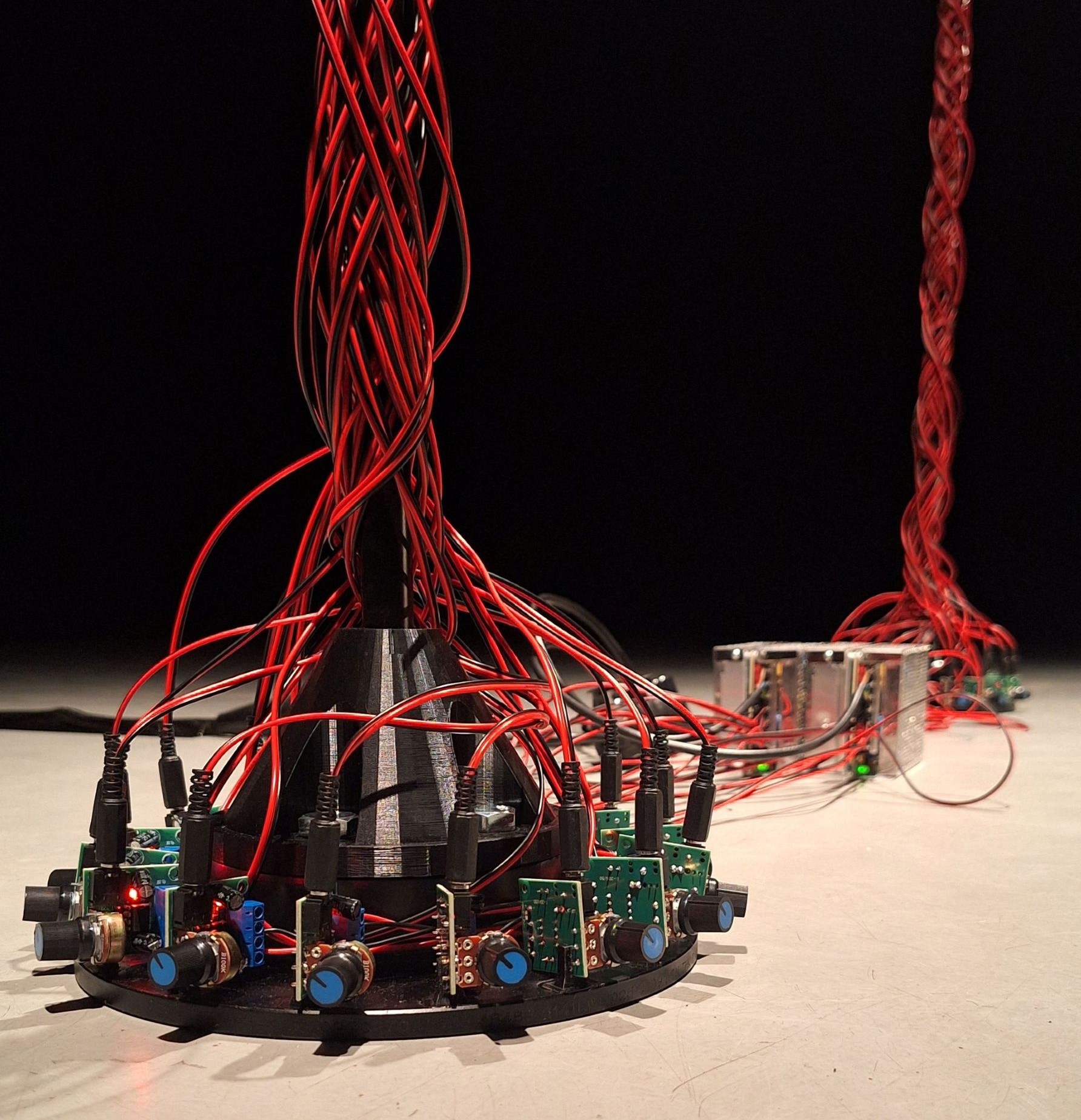

Base of the sculpture with amplifiers and cables (photo: Caeso) -

The assembled sculpture (photo: Caeso)